Page 2 - JAS-射流式曝氣攪拌系統-20220221

P. 2

前言 FORWORDS

生物處理是當今廢水處理中最為經濟有效之處理程序,主要分為好氧及厭氧兩大類型,其中

JAS

好氧處理最為普遍約佔80%以上,好氧處理成敗的關鍵在於是否選用優良高效的曝氣系統,

得以用最低的動力將空氣中的氧溶解於水中,除供給微生物分解汙染質所需的氧氣,並可產

生良好的攪拌混合效果,避免生物汙泥之沉澱累積。川源JAS射流式攪拌曝氣系統,可適用於

調勻池、曝氣池及任何好氧性之生物處理系統,如氧化渠、氧化塘或SBR;其可完全混合攪拌

的特性,更適合用於較長汙泥齡(SRT)之高MLSS的活性污泥法及深層曝氣處理的場合。

本套系統,亦可透過控制空氣量的方式,作為脫氮denitrification、硝化nitrification等處理程序

配套設備

Biological treatment is the most economical and effective treatment process in wastewater treatment today.

It is mainly divided into two types: aerobic and anaerobic, of which aerobic treatment is the most common, a

ccounting for more than 80%. The key to the success or failure of aerobic treatment is whether to choose an

excellent and efficient aeration system. It can dissolve the oxygen in the air in the water with the lowest power,

In addition to supplying the oxygen required by microorganisms to decompose pollutants, it can produce a

good stirring and mixing effect to avoid the accumulation of biological sludge. JAS jet mixing and aeration

system can be applied to leveling tanks, aeration tanks and any aerobic biological treatment systems,

such as oxidation channels, oxidation ponds or SBR; its characteristics of complete mixing and stirring are

more suitable for use for long sludge age (SRT) high MLSS aactivated sludge process and deep aeration treatment.

1 This system can also be used as supporting equipment for processing procedures such as denitrification and

nitrification by controlling air volume.

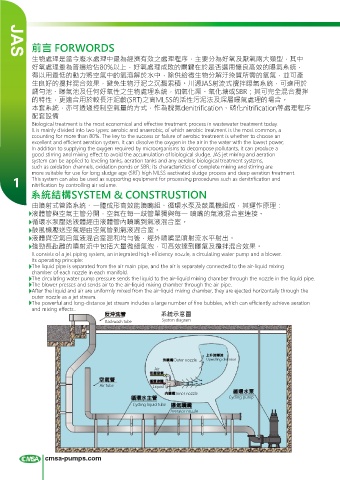

系統結構SYSTEM & CONSTRUSTION

由噴射式管路系統、一體成形高效能噴嘴組、循環水泵及鼓風機組成,其運作原理:

液體管與空氣主管分開,空氣在每一歧管單獨與每一 噴嘴的氣液混合室連接。

循環水泵壓送液體經由液體管內噴嘴到氣液混合室。

鼓風機壓送空氣經由空氣管到氣液混合室。

液體與空氣自氣液混合室混和均勻後,經外噴嘴呈噴射流水平射出。

強勁長距離的噴射流中包括大量微細氣泡,可高效達到曝氣及攪拌混合效果。

It consists of a jet piping system, an integrated high-efficiency nozzle, a circulating water pump and a blower.

Its operating principle:

The liquid pipe is separated from the air main pipe, and the air is separately connected to the air-liquid mixing

chamber of each nozzle in each manifold.

The circulating water pump pressure sends the liquid to the air-liquid mixing chamber through the nozzle in the liquid pipe.

The blower presses and sends air to the air-liquid mixing chamber through the air pipe.

After the liquid and air are uniformly mixed from the air-liquid mixing chamber, they are ejected horizontally through the

outer nozzle as a jet stream.

The powerful and long-distance jet stream includes a large number of fine bubbles, which can efficiently achieve aeration

and mixing effects..

Backwash tube System diagram

Outer nozzle Upwelling diversion

Air

Air tube Liquid

Inner nozzle

Cycling pump

Cycling liquid tube

Arerator nozzle

cmsa-pumps.com